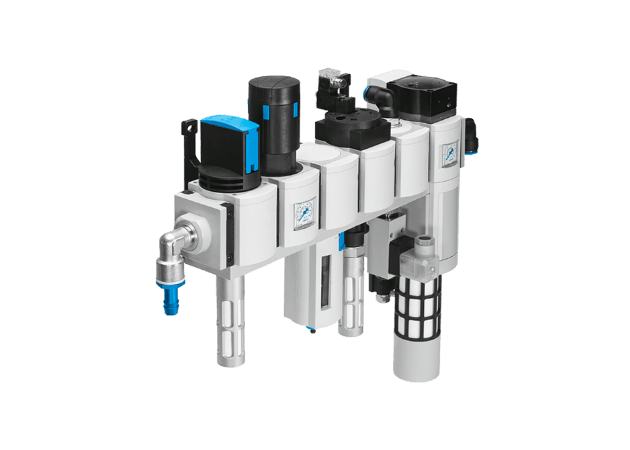

ISO certified air filter units.

Get a quote

Get a quote

Key Features

LAB air bearing stages require pressurized air in well-defined conditions to guarantee the optimal performance and the unlimited lifetime of the air bearing systems as intended by our R&D team. Therefore, we provide a selection of air filter accessories to alleviate the task of air preparation.

Our products require clean, oil-free and dry air at a constant air pressure to be delivered to the motion stages. LAB uses the ISO 8573-1:2010 Class 1.3.1 standard to specify the required air quality. The requirements included in this standard are listed here.

To achieve these stringent air quality levels, a careful approach to component selection is needed. When using an oil-free air compressor and storage tank with draining point, LAB’s air filter units can be used to reach the required air quality level. The following schematic shows a layout of the general system setup.

Class 1: particulate

Class 3: water

Class 1: oil

Related products

Product finder

-

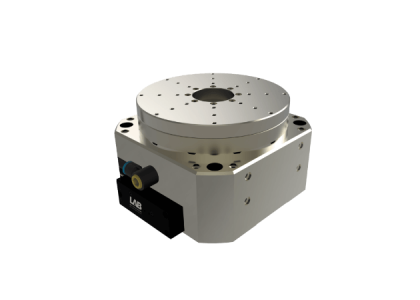

RT150AU

Type: air bearing

Load: 72 kg

Precision: < 20 nm

Speed: 200 RPM

-

Drivebox 3.6

Versatile controller

Use with LAB stages

Highly configurable

Easy setup

-

Slip Rings

To combine stages

Multi-axis systems

Electrical pass through

Fluid & gas options

-

Air Filters

ISO certified

For air bearings

Guarantees performance

Guarantees lifetime