OEM services

Our approach

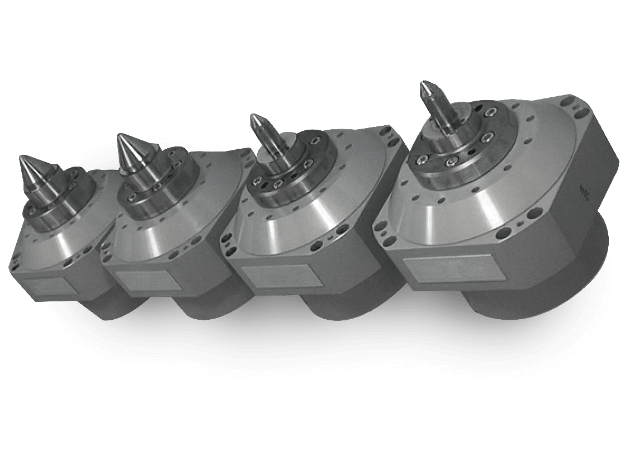

We are experienced in serving our customers with custom made rotary stages or customized multi-axis motion systems. Manufacturers of high-precision machines and metrology equipment rely on us to build prototypes from scratch or build upon one of our standard product solutions. We distinguish our OEM services into two important project phases: prototyping and mass production.

Start your project

Prototyping

Early on we study your specifications and work with you to decide whether to build a new solution from scratch of to modify an existing LAB Motion Systems product. Technical models are adapted and customized to meet your specific requirements.

Critical subsystems are developed and tested first. We provide you with measurement reports to validate the specifications can be achieved. In close cooperation the design will be frozen and several prototypes are made and tested by us and you. If all tests are successful, the project is ready to enter the production phase.

Start your design

Series Production

We have a proven track record in setting up and maintaining mass production of customized solutions. Every finalized unit will have the same specifications, delivered on time with reliable quality and ready to run smoothly for years and years. Our testing and quality control department makes sure that every shipped product or system complies with your exact specifications. Moreover, by reporting us your monthly updated volume forecasts, you enable us to deliver products fast and with reliable shipping times.

Start your production

Additional services

Maintenance

Simulation

Training

We have a proven track record in mass production of customized solutions.

Read more

Contact our team

Products

Custom solutions