Case study

RT series & slip ring

At LAB Motion Systems we have accumulated a large know-how on the successful integration of sliprings and rotary unions. Integrating them without compromising the precision of the air bearing rotary stage is challenging.

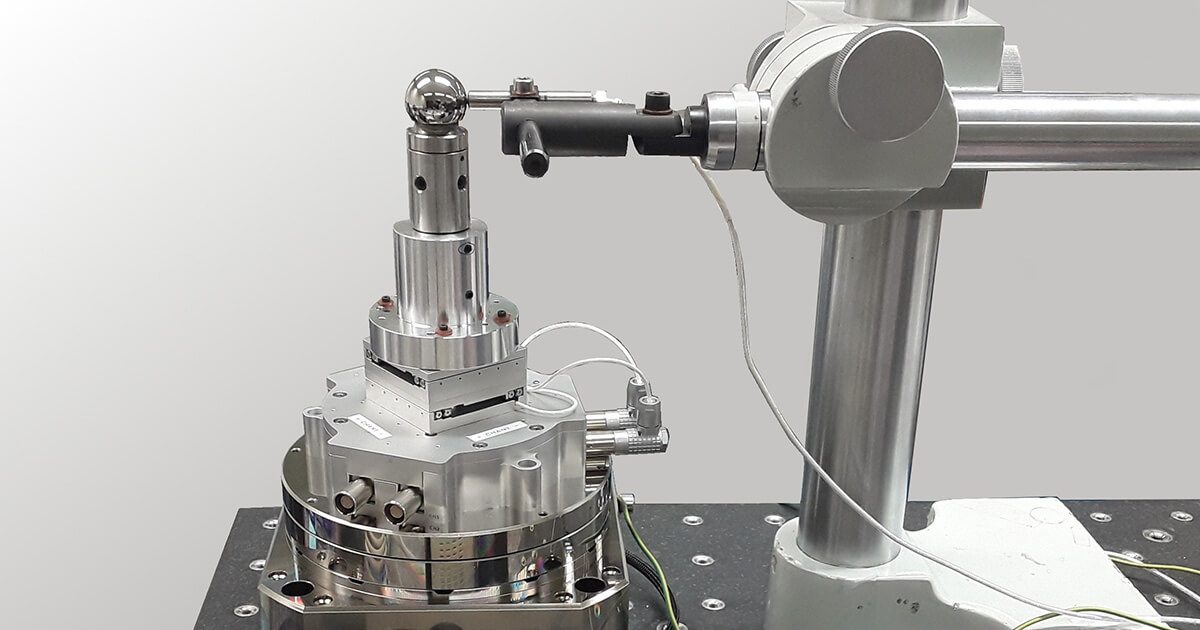

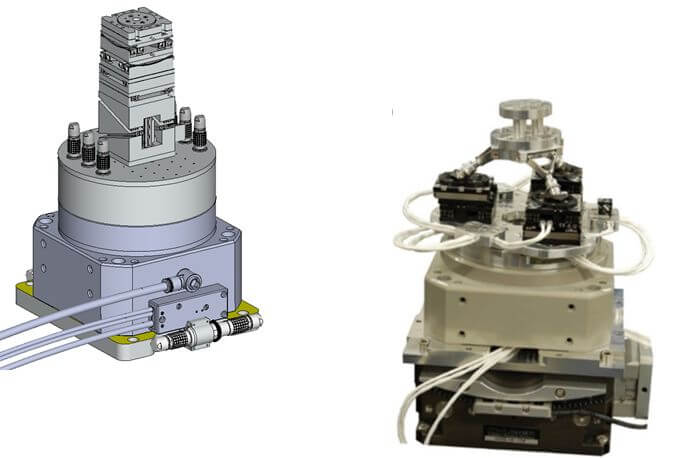

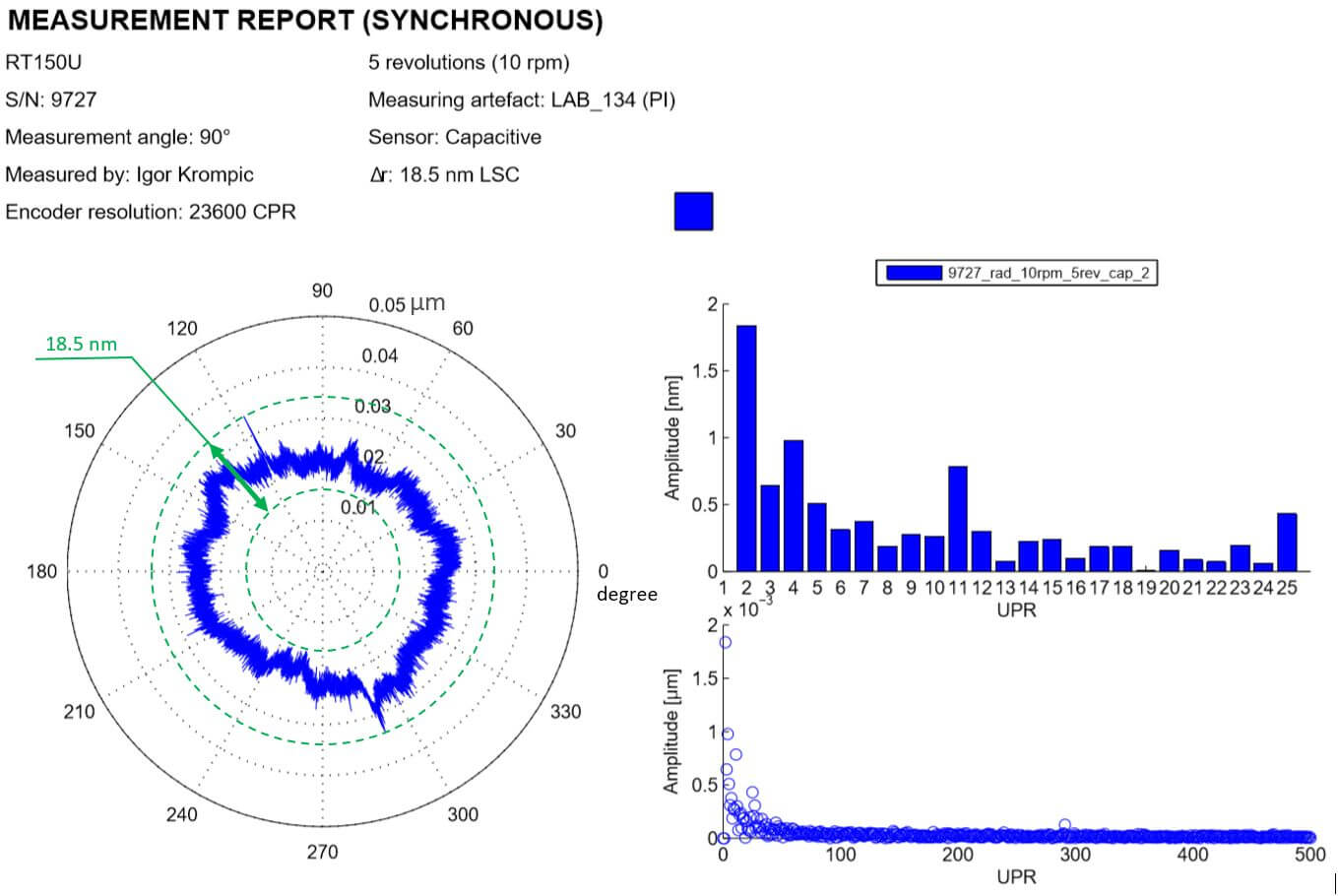

The figure below shows an RT150AU rotary stage with a 24 wires slipring for connecting an XYZ stage from a partner. The radial error motion of the complete setup was measured with capacitive probes and the addition of the slipring only increased the radial error motion to 18.5 nm.

“We have extensive know-how on successful integration of slip rings and rotary unions.”

Kurt Smets – Product Development Manager

Featured products

More products

Slip Rings

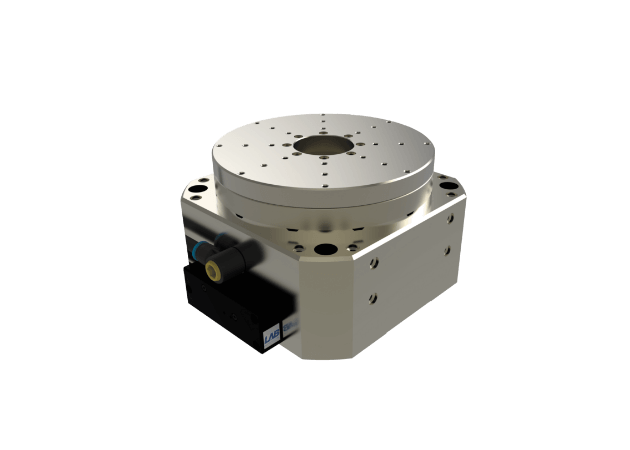

RT150AU

Drivebox

More stories

All cases

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.

The 5-Axis Motion Machine

A 5-axis motion machine incorporates a rotary stage positioned on top. This machine is a significant breakthrough for our client, as it opens up new possibilities in X-ray and CT imaging for a wide range of objects.

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.