Case study

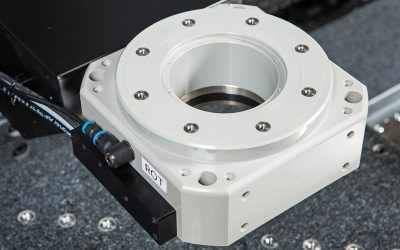

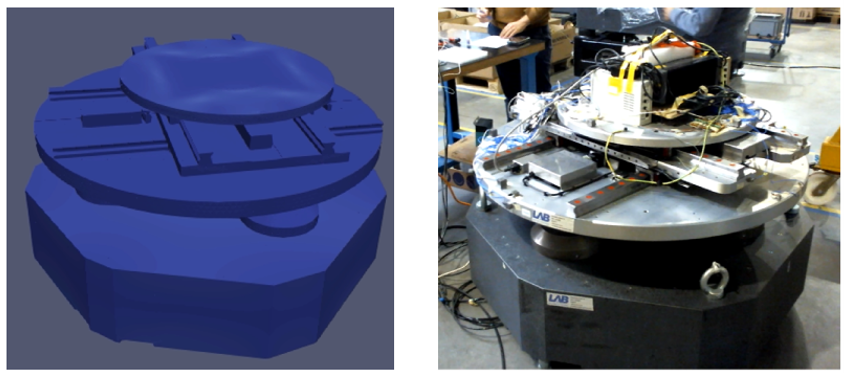

Study with Siemens: Smart virtual sensing on our air bearing stage.

Can we use a forward simulation to predict broadband vibrations of our air bearing stage after a hammer impact? And what is the increase in accuracy that we can achieve with the Smart Virtual Sensing technology?

First, we had to evaluate if we can predict broadband vibrations of our air bearing stage after hammer impact with a pure forward simulation. Then we assessed what the increase is in accuracy of such prediction when using smart virtual sensing.

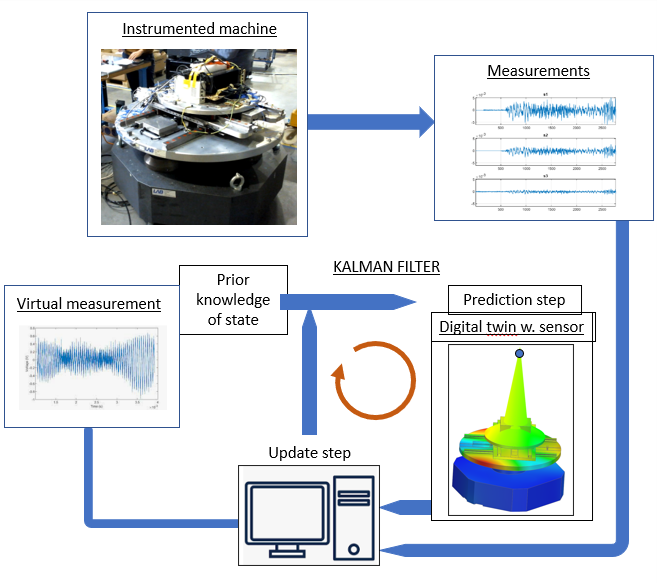

What is smart virtual sensing?

A technology that combines a digital representation of a system with a set of measurements through a mathematical process to perform virtual measurements.

The measurements allow us to correct the virtual model and bring its behavior closer to that of the physical machine. This also opens up new possibilities, including the ability to perform real-time measurements at locations that are difficult or virtually impossible to instrument. Additionally, the use of measurements can help reduce overall measurement costs.

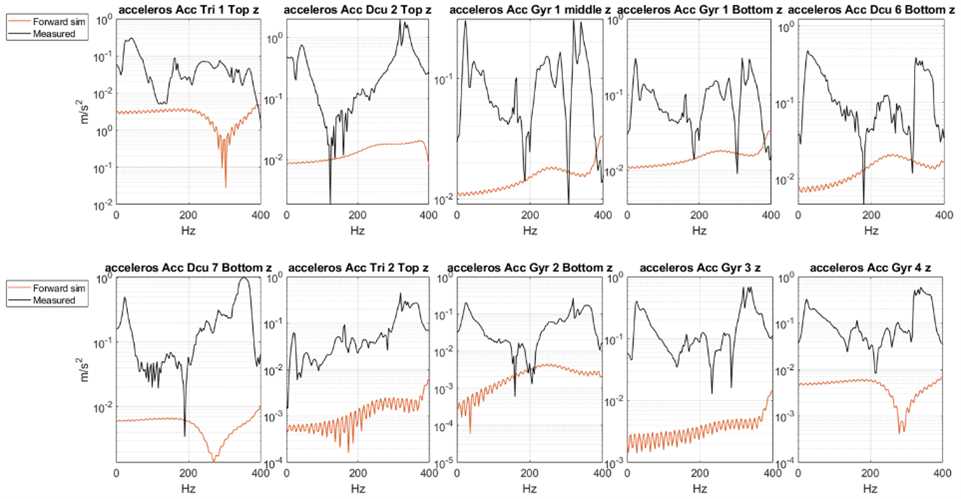

Validation Case. Forward simulation.

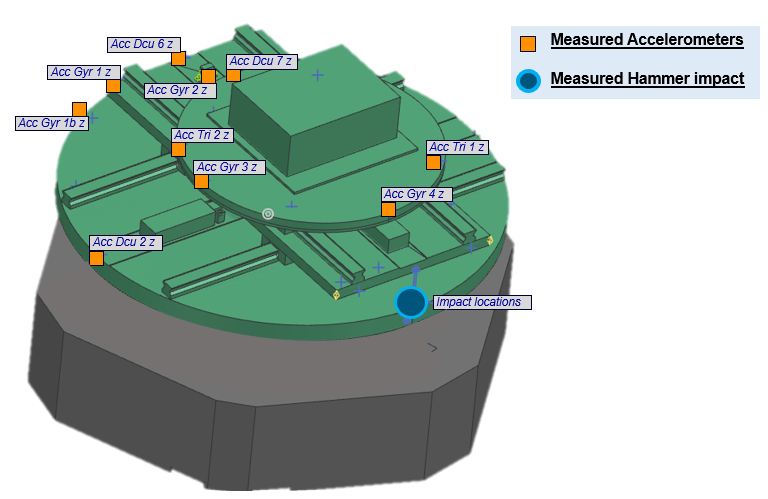

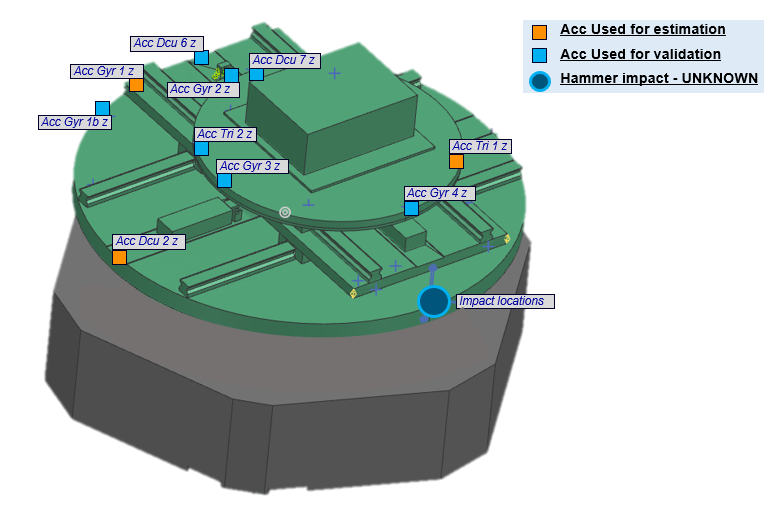

The force measured during a hammer test is fed as input to a linear FE model of our air bearing stage, developed for X-ray imaging on large samples. The accelerations at several sensor locations are extracted from the model and compared with physical measurements.

State-of-use. Forward simulation with known input.

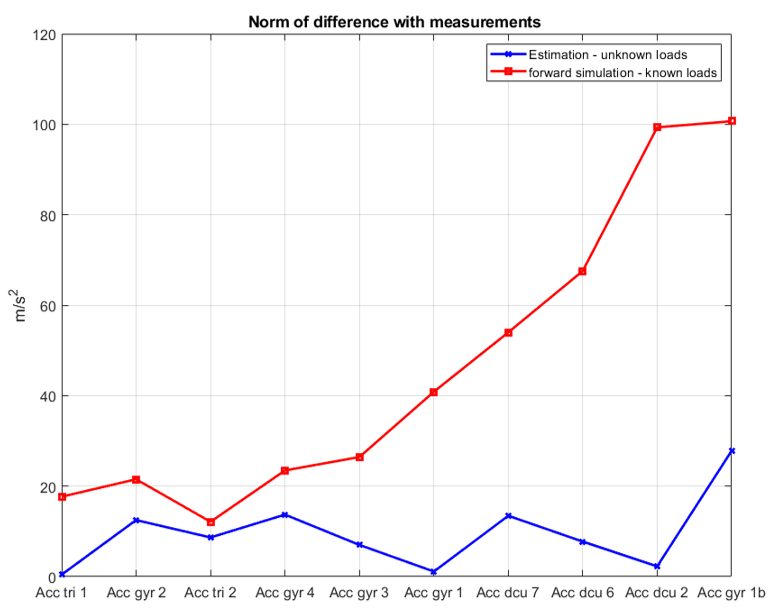

Due to the complexity of the system, the model cannot represent the vibrations. This is due to the presence of missing physics that are extremely difficult to model, and in some cases, may not be possible to model at all. These complex physics are triggered from broadband vibrations.

Validation Case. Smart Virtual Sensing solution.

Data from 3 accelerometers are used as input to estimate the response of the system at several locations on the model (the smart virtual sensor locations). The response at the virtual sensor locations are compared against the virtual measurements to validate the accuracy.

The hammer impact force is not used.

Simcenter 3D Smart Virtual Sensing solution.

Estimation with unknown input.

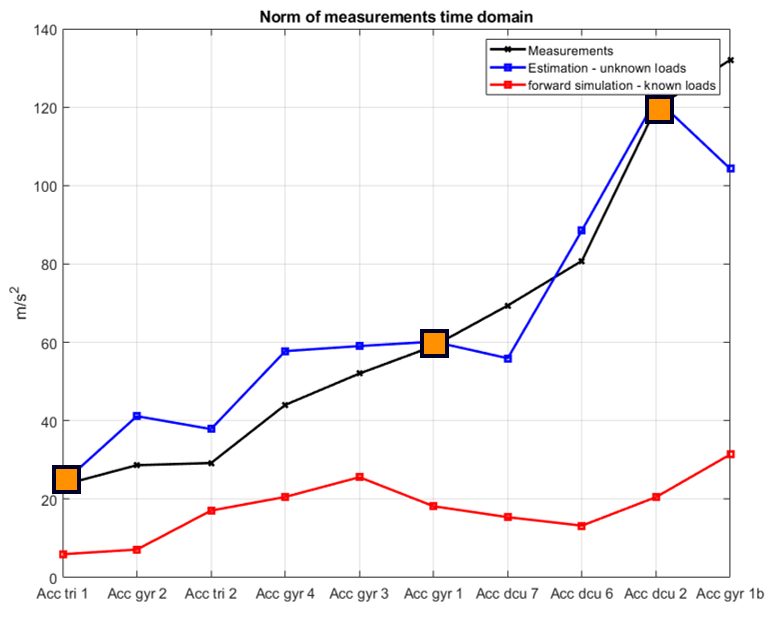

The system uses three accelerometers as input, and the input load is considered unknown. Based on the data from these accelerometers, the virtual measurements are estimated. These virtual measurements can be compared to physical data to validate the approach. The overall results can be compared to the state-of-use to provide an overview of the system’s performance.

Drastic improvement in accuracy using the same model and without using the input load measurements.

Through our study, we have demonstrated how a creative and innovative approach to designing a rotary air bearing stage can achieve high accuracy at a competitive cost and production effort. We have also shown how implementing smart virtual sensing in our system can improve the estimates of critical machine parameters at a low cost. Moving forward, our next steps involve utilizing dynamic multi-body models of the rotary stage to perform virtual measurements on dynamic machine parameters, such as error motion, through smart virtual sensing.

“We realize complete integrated motion systems for a variety of industries and clients.”

Kurt Smets – Product Development Manager

Featured products

More products

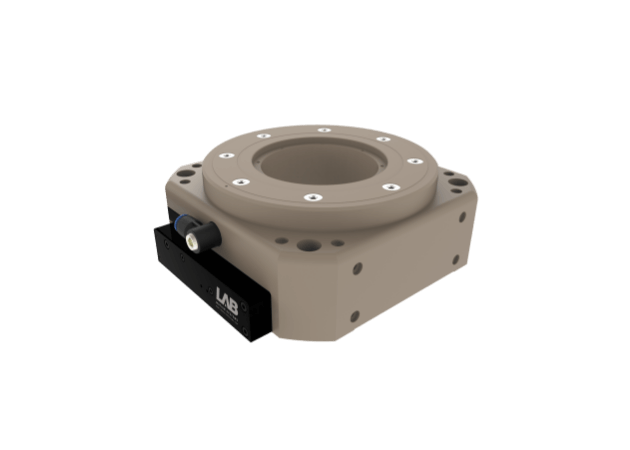

RT150AX

Drivebox

Air Filters

More stories

All cases

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

The 5-Axis Motion Machine

A 5-axis motion machine incorporates a rotary stage positioned on top. This machine is a significant breakthrough for our client, as it opens up new possibilities in X-ray and CT imaging for a wide range of objects.

4 Axis Motion System

A combination of standard products, customized products and a custom developed air bearing vertical stage. All axis can be driven and synchronized by LAB’s motion controllers or with commercially available controllers.

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

The 5-Axis Motion Machine

A 5-axis motion machine incorporates a rotary stage positioned on top. This machine is a significant breakthrough for our client, as it opens up new possibilities in X-ray and CT imaging for a wide range of objects.