Case study

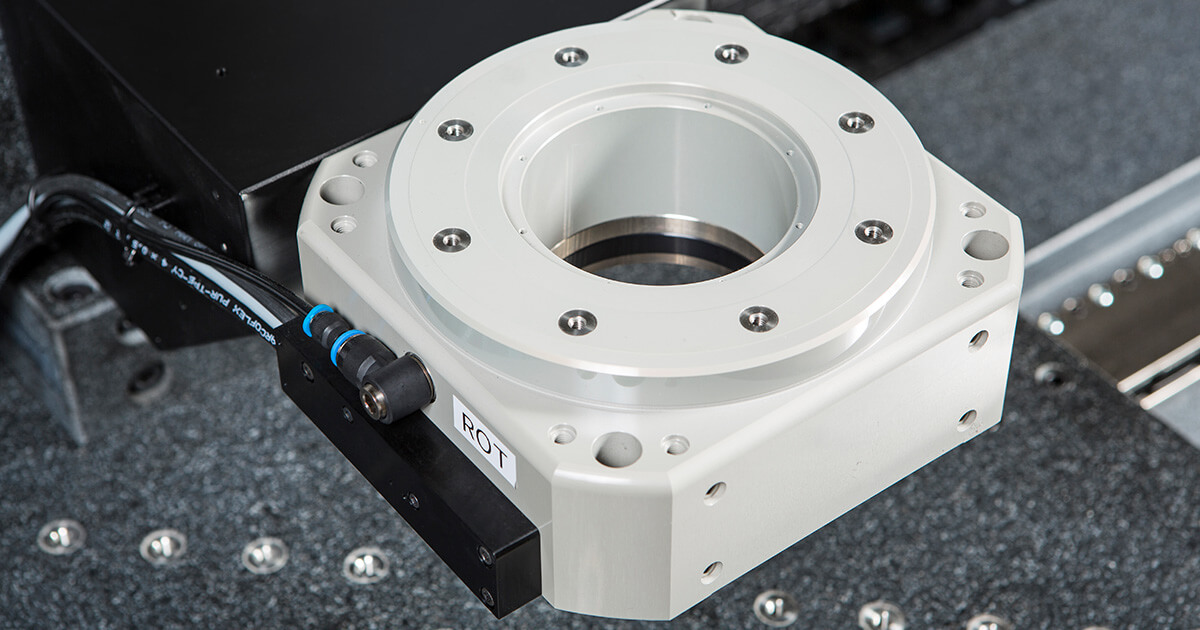

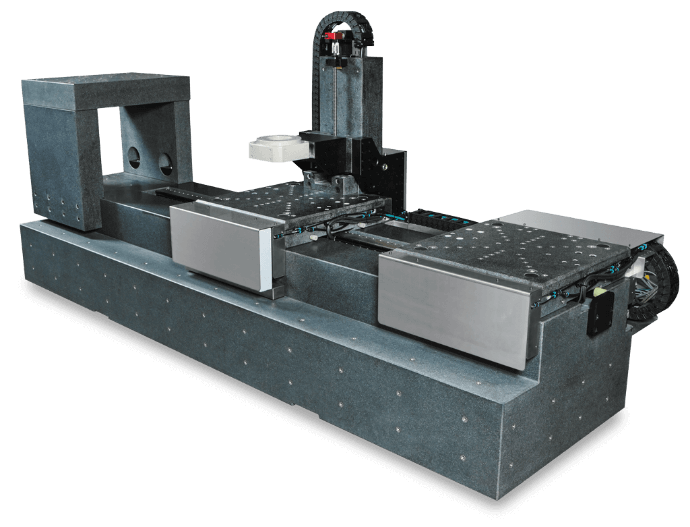

4 axis motion system

This 4-axis system is a combination of standard products, customized products and a custom developed air bearing vertical stage.

Customers rely on our extensive knowledge of mechatronics and control engineering, as we translate your needs into a complete solution. LAB is the right partner to translate abstract ideas into feasible concepts and reliable prototypes. Our state-of-the-art production facilities are used to create and assemble customized products to meet the demands of our customers. We proudly offer our clients a custom solution, starting from concept generation to development up to series production.

Custom services range from high-performance systems for the semiconductor industry to all high-precision manufacturing equipment. LAB Motion Systems supports the development from the initial study into the complete system design, manufacturing and assembly process. Whether you are working on a unique product or in need of a yearly production capacity: we surely have the right solution for you!

What we do

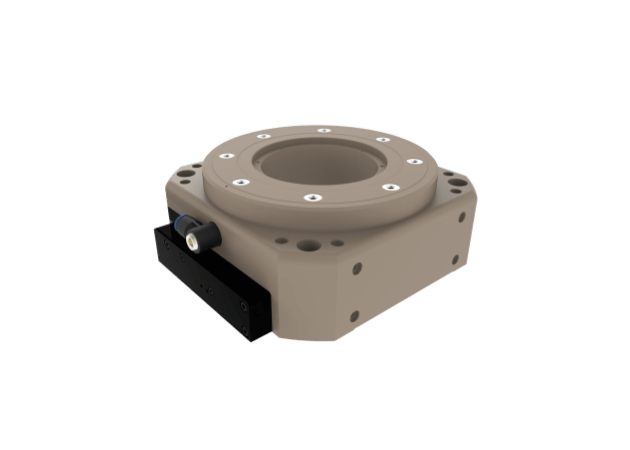

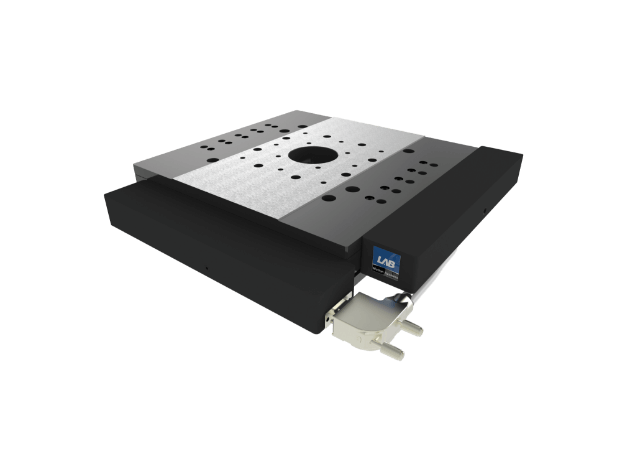

The Systems group is specialized in complete systems that are adapted to dedicated customer requirements. Therefore, our machines are very diverse in composition and functions. Our main focus are systems that meet high demands in the field of precision (precisions lower than 1 µm!). Depending on the required motion, we offer both air bearing and ball bearing solutions for linear and rotational movements.

We will realize your high-performance motion system from scratch in record time! This is achievable by our inhouse series of linear and rotary stages, which can be easily customized by LAB’s team of development engineers and designers.

Our motion systems are a combination of several movement directions. Systems with 7 motion axes (and more!) are part of our expertise. Additionally, synchronized movements of different axes and bridge systems can be offered. We also supplie you with a general operating control system, which allows the user to monitor and guide the desired movements.

How we do it

Because of the profound knowledge of bearing technology, LAB Motion Systems is capable of making fully customizable axial movement. Different motion axes can be integrated smoothly together, resulting in a system that performs excellently due to its compactness and stiffness.

For the design of these customized systems, LAB Motion Systems has a team of experts available. We adopt a mechatronic approach: servo drivers, control software, motors and bearings are all dimensioned and developed specifically for each application. Furthermore, crucial parts or assemblies are calculated with the help of simulations.

Key applications

We produce systems for a wide range of applications where the need for precision movements is a central focal point. In general, there are two categories: precision production machines and positioning systems for measuring equipment.

Production machines

can be high-speed pick-and-place machines, (micro) laser cutting and welding machines, fly cutter machines for surface treatments, …

Positioning machines

include X-ray applications, semiconductor inspection and laser equipment. LAB Motion Systems has extensive experience in these fields. Often sample positioning machines exist of precise linear moving axes (horizontally and vertically) with an integrated rotary stage and a cross stage on top.

“We realize complete integrated motion systems for a variety of industries and clients.”

Kurt Smets – Product Development Manager

Featured products

More products

RT150AS

Drivebox

CT250B

More stories

All cases

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.

The 5-Axis Motion Machine

A 5-axis motion machine incorporates a rotary stage positioned on top. This machine is a significant breakthrough for our client, as it opens up new possibilities in X-ray and CT imaging for a wide range of objects.

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.