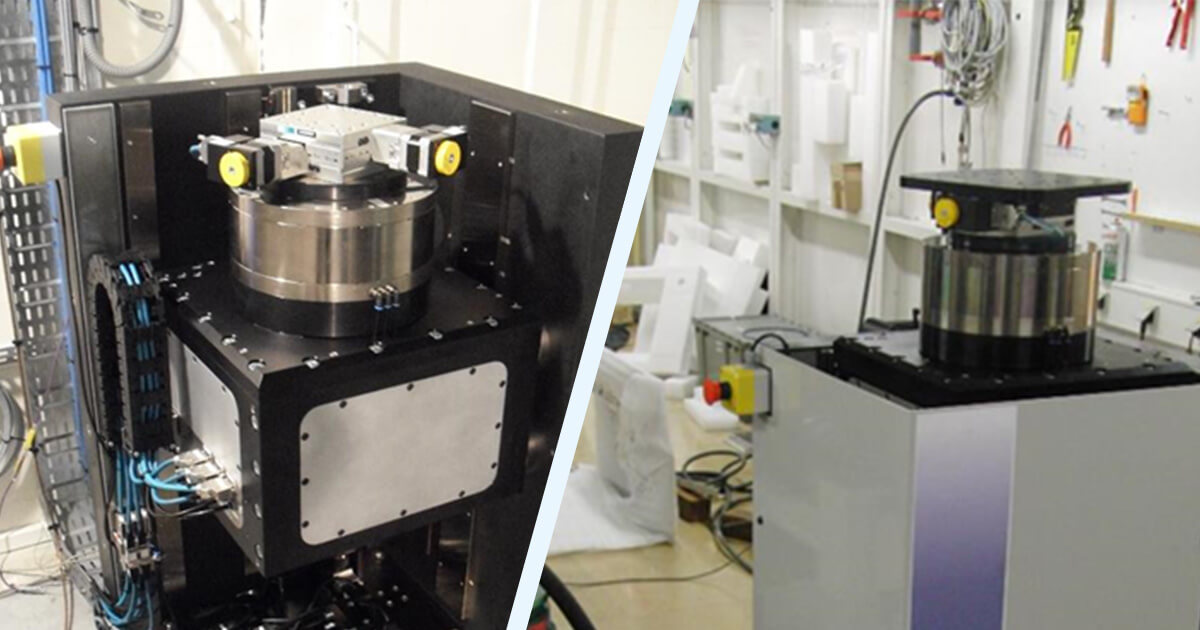

Case study

Sample stage for 3D imaging

A large size sample stage was developed in cooperation with the ESRF (ID19) to position and scan samples for high resolution multi-scale microtomography and laminography. The 5 axis system has a 600 mm long vertical stroke allowing to scan large objects using helical scanning techniques. The 500 mm horizontal linear axis allows scanning of large 2D samples and recording “bright-field” images (without sample in the beam) for data normalization and correction

Since we delivered it, this system has become the popular workhorse for doing a wide variety of measurements.

A similar custom made solution can be made for your requirements. At LAB Motion Systems we specialize in turning your exceptions in a great solution.

“This system has become our customers’ popular workhorse for measurements tasks.”

Kurt Smets – Product Development Manager

More stories

All cases

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.

The 5-Axis Motion Machine

A 5-axis motion machine incorporates a rotary stage positioned on top. This machine is a significant breakthrough for our client, as it opens up new possibilities in X-ray and CT imaging for a wide range of objects.

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.