Case study

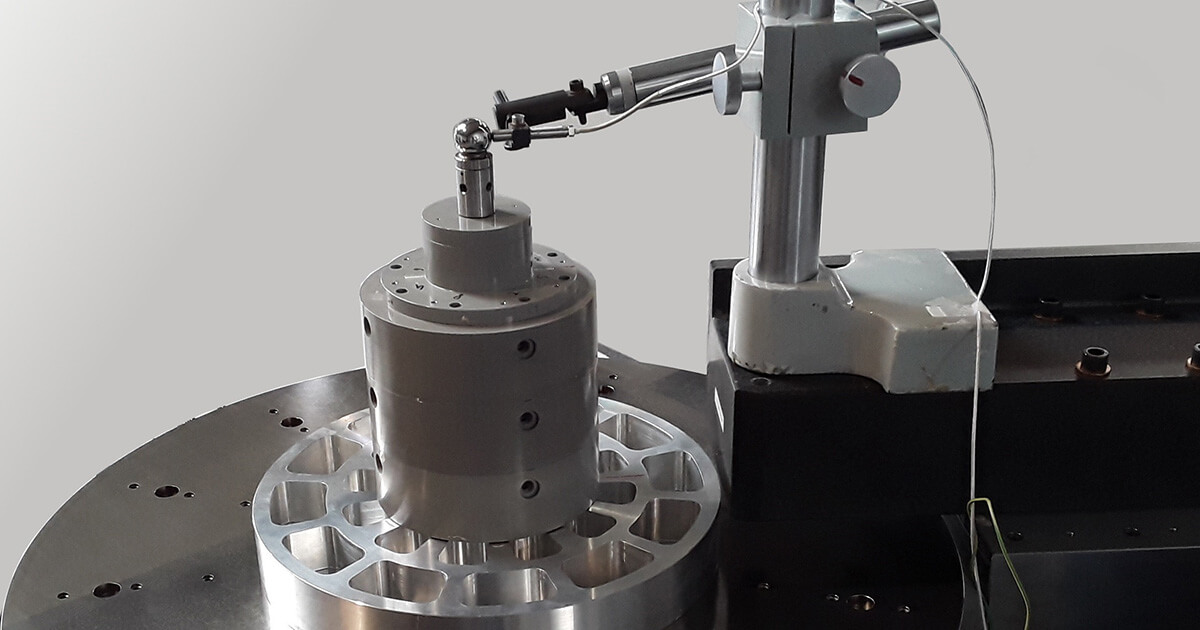

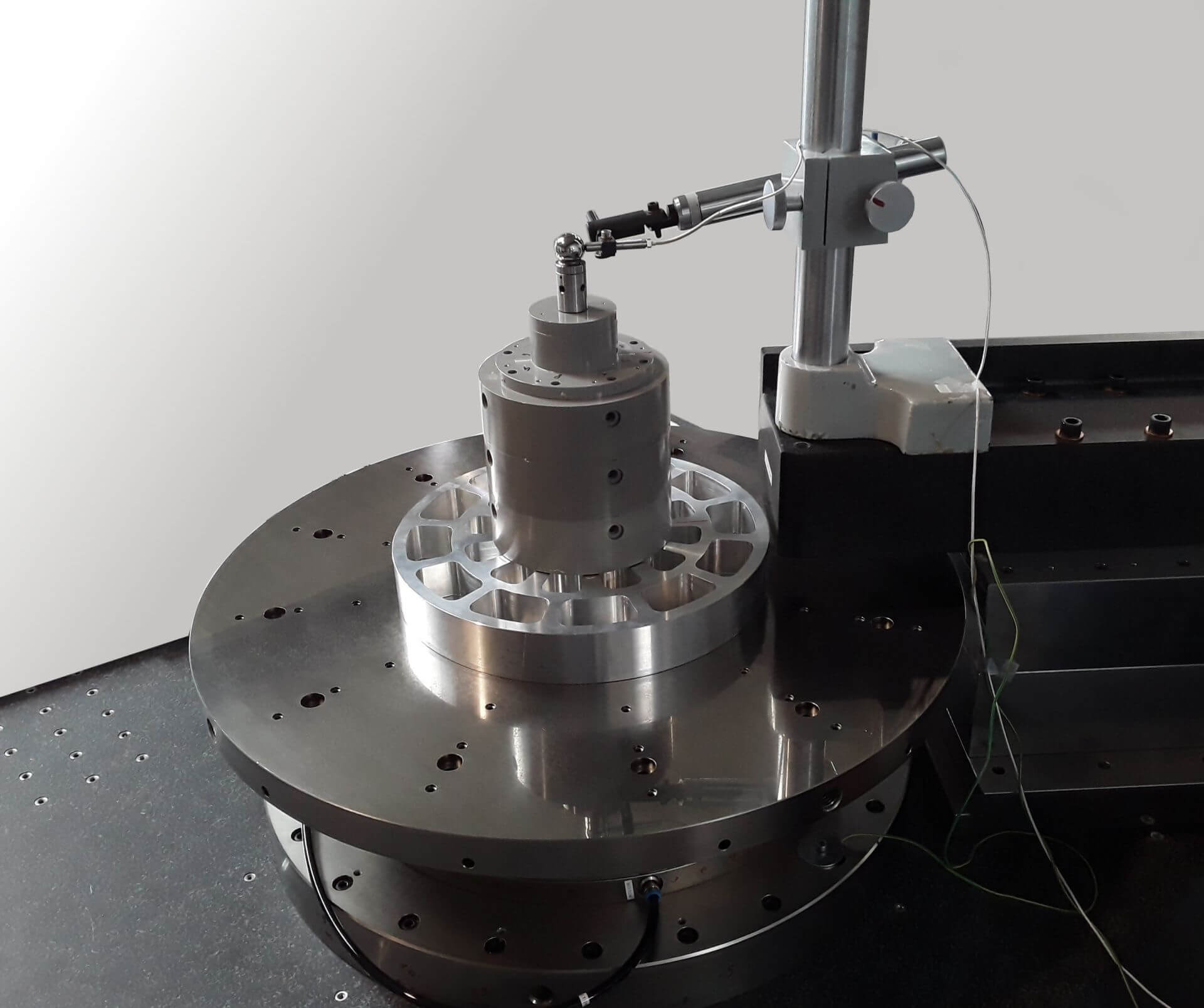

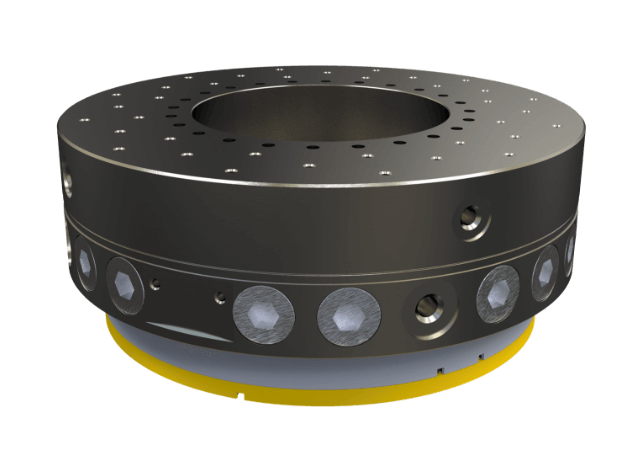

Air bearing for lens alignment

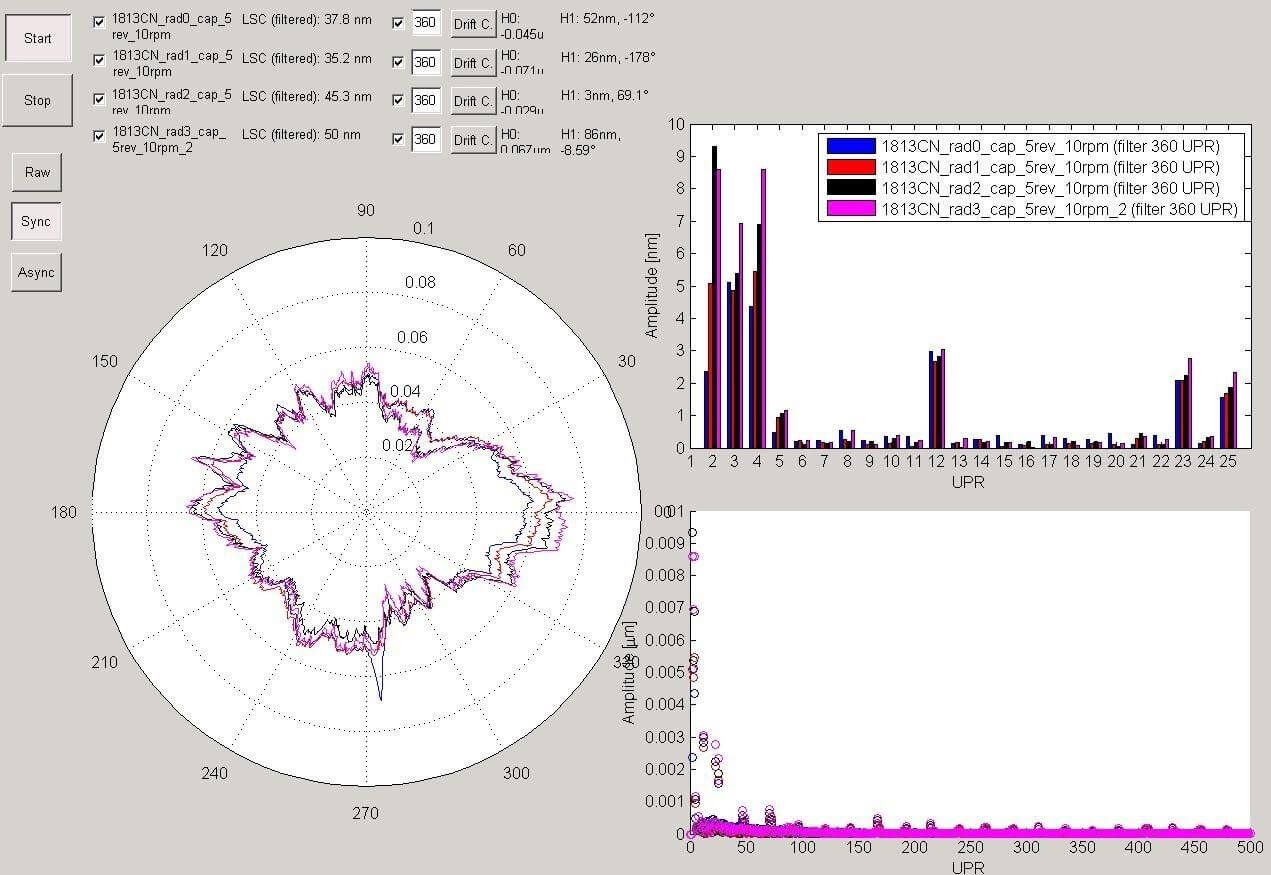

This customer needed an ultra-precise rotary stage for aligning optics for lithography systems. The challenge in this project was to combine the high load requirement with nano meter level error motions. As the optics assembly was very high the wobble of the rotation stage needed to be exceptionally low.

“The challenge was to combine the high load requirement with nano meter level error motions.”

Kurt Smets – Product Development Manager

Featured products

More products

Drivebox

RT500AS

Air filter

More stories

All cases

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.

The 5-Axis Motion Machine

A 5-axis motion machine incorporates a rotary stage positioned on top. This machine is a significant breakthrough for our client, as it opens up new possibilities in X-ray and CT imaging for a wide range of objects.

Optimizing Wafer Inspection with Air Bearing Stages

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy.

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.