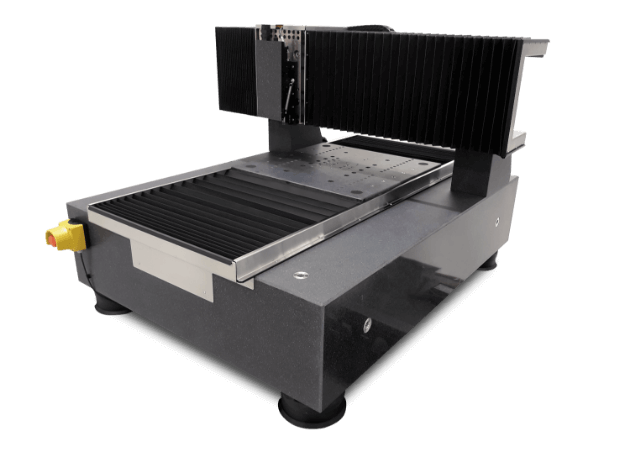

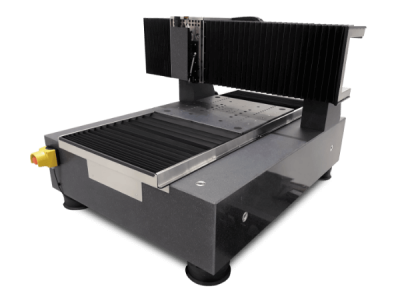

Built for optical inspection tasks.

Get a quote

Get a quote

Key Features

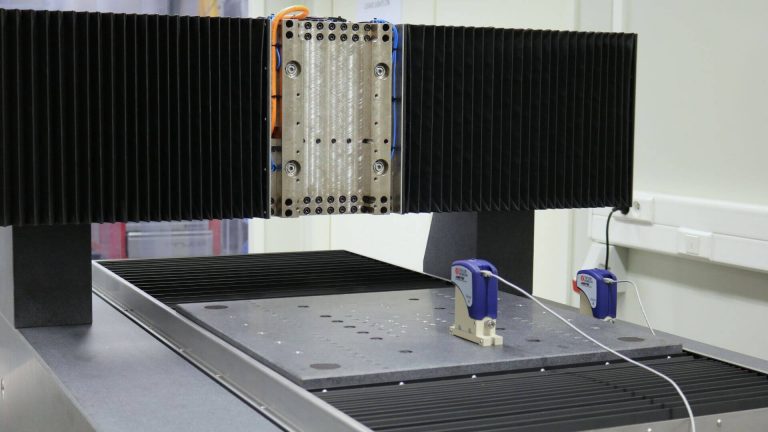

This double axis motion stage consists of two air bearing axis. The bottom one uses a solid granite base with a moving granite platform on top. On the gantry the second axis has a moving steel platform running over a granite bridge. A sub-micron flatness is achieved making this system ideally suited for inspection machines with the highest demands in precision motion and positioning. Our team created a modular system, so please get in touch if you have a special request for a gantry system.

Load capacity up to 50 kg

Stroke 310 x 310 mm

Precision air bearing for ultra-smooth motion

Extreme low sub-micron flatness error

Specifications

| Stroke | 310 x 310 mm |

|---|---|

| Size moving platform X | 450 x 450 mm |

| Outer dimensions LxWxH | 1050 x 920 x 850 mm |

| Total mass | 950 kg |

| Load capacity X | 50 kg |

| Load capacity Y | 8 kg |

| Speed | 300 mm/s |

| Acceleration | 0,5 m/s² |

| Encoder resolution | 20 nm |

| Repeatability | 0,1 µm |

| Accuracy | < 1 µm |

| Flatness X , Y | 1 µm |

| XY combined flatness over 300 x 300 mm area | < 1 µm |

| XY orthogonality | 10 µrad |

| Pitch | ± 5 µrad |

| Yaw | ± 5 µrad |

| Roll | ± 5 µrad |

More products

Product finder

-

GT600LA

Stroke: 610 x 610 mm

Load: 150 kg

Resolution: 20 nm

Speed: 300 mm/s

-

GT300LA

Stroke: 310 x 310 mm

Load: 150 kg

Resolution: 20 nm

Speed: 300 mm/s

-

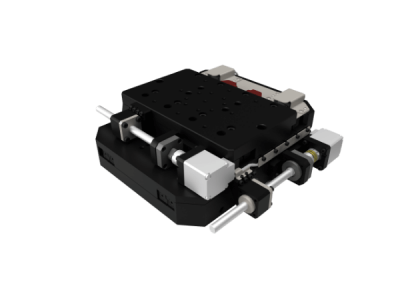

XY250B-100

Pair with rotary stages

Load: 80 kg

Incr. motion: 0,1 µm

Stroke: ± 50 mm

-

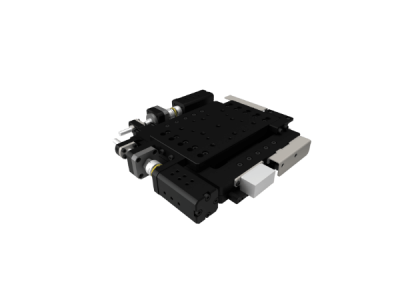

XY150B-12

Pair with rotary stages

Load: 10 kg

Incr. motion: 0,1 µm

Stroke: ± 6 mm